Torre CALEIDO

The Challenge

Building on the foundations of the former Madrid Congress Centre as well as removing all architectural barriers.

The architectural studio Fenwick Iribarren, in co-authorship with the studio Serrano Suñer Arquitectos, has been commissioned to design this new architectural complex.

The Outcome

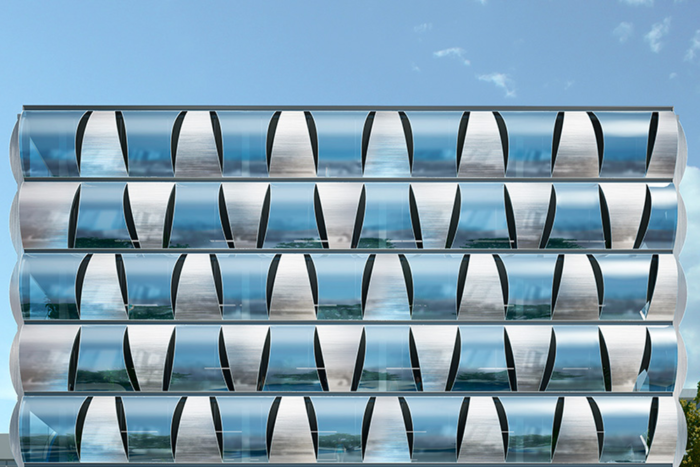

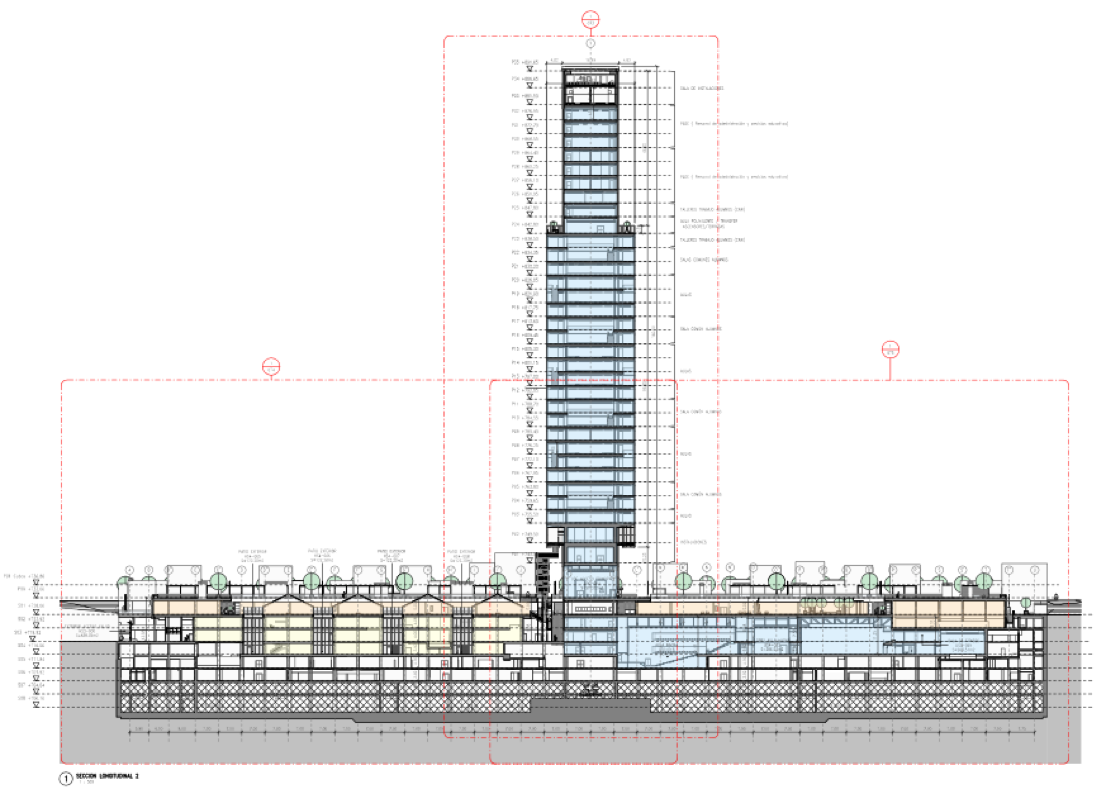

A building made of two parts, a horizontal and a vertical “city”, in an “inverted T” shape, that differs from everything that has been built so far, and that achieves the humanization of the environment through people who generate talent, innovation and technology.

The entire tower will be used by Instituto de Empresa (IE), which will set up the first high-rise university campus in Spain. The base of the building will house various shops, a catering area and a first-rate health centre managed by Quirón Salud, in addition to other spaces IE will have available.

METHODOLOGY

CONSTRUCIA INSTALACIONES decided to apply all its technical knowledge using the methodologies used in the company.

Lean Methodology

LEAN methodology consists of optimising production time, increasing efficiency by eliminating everything considered useless.

Useless is considered to be the time in which the production is in the waiting or inactivity phase.

The optimization is achieved through planning and coordination, obtaining detailed planning that includes the specific programming of each delivery, getting it done “just in time”.

In Caleido, LEAN methodology is based on four fundamental pillars.

- HUB (Logistics centre)

With a location close to the construction site, our HUB allows us to have greater control of deliveries, achieving Just in Time deliveries to construction sites.

It allows us to carry out the essential prefabrication work, which not only does save time but also reduces the number of staff on site, avoids unnecessary stockpiling on site and arranges shipments by day and area.

- PREFAB

One of the fundamental aspects in Caleido, which has allowed us to increase work performance, improving working conditions and allowing us to reduce completion times.

- REGULAR PARTNERS

Caleido has allowed us to subcontract industrialists familiar with LEAN methodology, who were trained in the methodology.

This has allowed us to strengthen our construction procedures, increasing productivity and reducing completion times and costs.

- LAST PLANNER

Caleido is our tool for the planning and coordination of the works, it allows us to control and guarantee the agreed objectives.

The objectives are set in a collective planning process, where the contractors participate from the beginning in the development of the main planning and the programme of each phase.

The last planner system (LPS) manages the commitments among the participants of the project, collaborating and implementing the construction planning schedule.

BIM Methodology

At Caleido we breathe BIM, this has allowed us to reach all our collaborators articulately, strengthening construction processes and speeding up their execution.

All this has been possible thanks to Construcia‘s commitment to new technologies, making them easier to use.

At Caleido, the main requirement is to move from an LOD300 to an LOD 500, with which the management of the model’s information is fundamental. To this end, we installed our own NAS for the work, which allows us to have all the information with immediate access for all the collaborators.

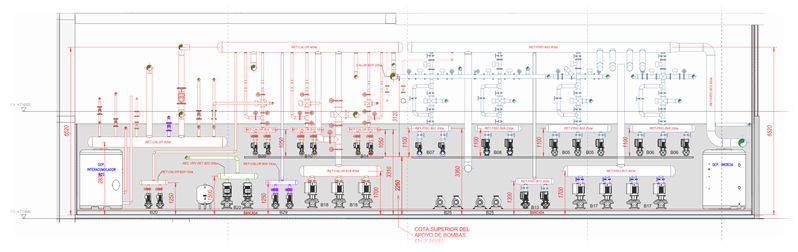

From the installation model, all the prefabrication and assembly plans for the site have been produced. By using different applications, we have managed to transfer the information almost in real time, allowing the site modellers to provide immediate solutions to any problems that may arise.

From the outset, Construcía Instalaciones has had the premise of making the model information easily accessible, which is why free applications with easy access for collaborators have been used whenever possible. This enabled us to experiment with different platforms obtaining very positive results that will allow us to apply them to our future works.

One of the most outstanding ones has been the use of Mixed Reality and Virtual Reality to our day-to-day work.

Augmented reality allows us to see in real time the overlay of the installations generated by BIM model in real spaces. To do this, we used company mobiles and tablets on site, providing a very practical tool for technicians and subcontractors. This technology was used when constructing production rooms in Torre Caleido.

We have used virtual reality as an immersive tour where the technician can walk around a production room and see in real scale the position of all its elements. In this way, we have been able to show our procedures to the subcontractors, who have appreciated the application of these platforms as it makes their work easier, facilitating decision-making.

Among the important investments made by Construcía Instalaciones to facilitate the implementation of BIM methodology is the purchase of a Faro scanning station. The laser scanner is already an important part of our protocols. This technology allows us to reliably transpose the changes that arise in the work, making the obtaining of As-Built documentation a smooth process, allowing us to obtain a 100% REAL mode, Providing our clients with a very important tool for the management of their assets.

We invite you to get to know us, we invite you to create the future together.